High Density Concrete

High density concrete is a concrete having a density in the range of 6000 to 6400 kg/cu.m. High density concrete is also known as Heavy weight concrete. High density concrete is mainly used for the purpose of radiation shielding, for counterweights and other uses where high density is required. The high density concrete has a better shielding property, so that it can protect harmful radiations like X-rays, gamma rays, and neutrons.

Whether, High Density Aggregates are used to achieve High Density Concrete ?

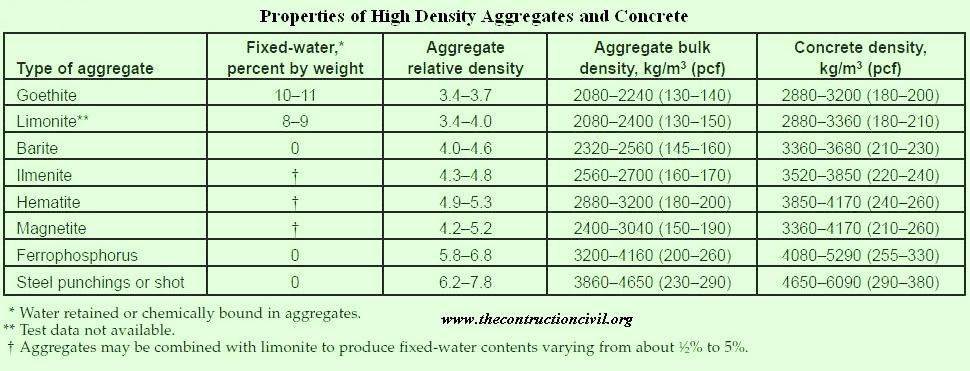

Yes, of course. High density aggregates are used to achieve heavy weight concrete. Some of the high density aggregates are, barite, ferrophosphorus, limonite, hematite, ilmenite, magnetite, goethite, steel punchings, and steel shots. The point to remember is that inorder to achieve this type of concrete, high fixed water content is required.

The selection of the above mentioned aggregates mainly depend upon the physical properties like bulk density, specific gravity, availablity of materials, and its expenses. In order to achieve workablility, high density the aggregates should be free from dirt, oil or grease stains and other foreign matter. Or else, it will retard the hydration process and the effective bonding of particles. Some of the boron additions like colemanite, borocalcite are used in the prepartion of concrete to improve the shielding properties. These additions may affect the setting time of concrete so, trial mixes should be made and tested depending upon the suitability.

Properties of High Density Concrete:

If steel punchings and steel shots are used we can achieve concrete having densities greater than 5000 kg/cu.m

Proportioning, mixing and placing of High Density Concrete:

* The mix proportions for these high density concrete is same as that of normal concrete.

* Conventional method of mixing and placing is used in high density concrete. The most important thing is to prevent overloading the mixer especially when heavy weight aggregates such as steels are used. Batch sizes should be reduced to 40 to 50% of the allowable mixer capacity. Also avoid excess mixing because it will result in workability and bleeding of concrete.

* Preplaced aggregate methods can be adopted when placing heavy weight concrete. In this method the aggregates are placed in forms , the appropriate grout made of cement, sand and water is pumped over the placed aggregates, so that they can fill the voids inbetween the aggregates. This method prevents the segregation of coarse aggregates also reduces drying shrinkage and helps us to achieve concrete of uniform density and composition.

* Puddling method can also be adopted. In this method, the mortar is placed in forms of 2″ thick and the coarse aggregates are placed over it and vibrated internally. Care should be taken that, the coarse aggregates are distributed evenly.

* Pumping of heavy weight concrete can be adopted only the height is limited. The heavy weight concrete cannot be pumped to larger distances because of their greater densities.